HomeProducts

Oil & Gas Equipment

- Oil & Gas Equipment

- DynamicLink Downhole Screen

- Flow Control

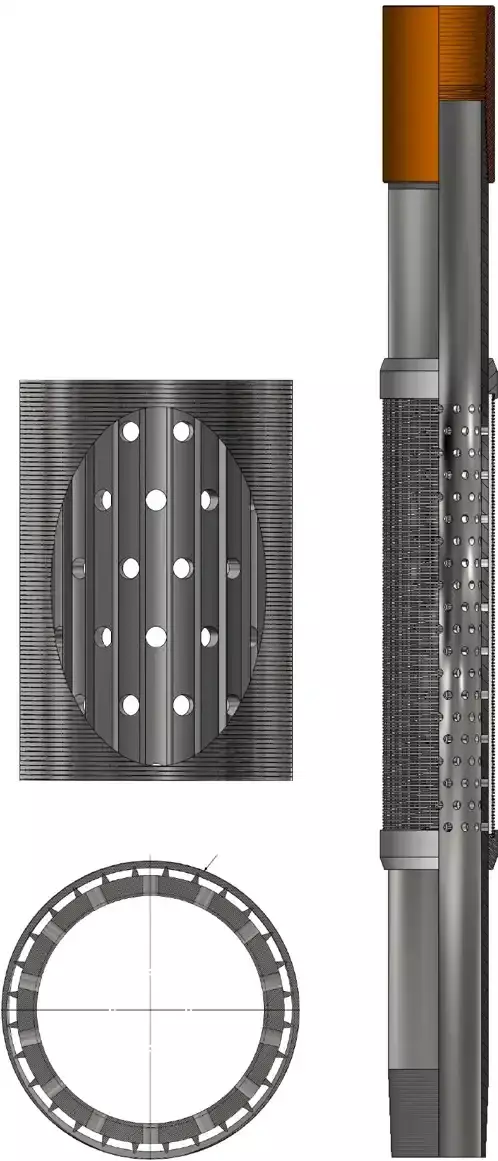

Fit To Base Screen Joint with Passive or Active Control Device

Overview

- The basepipe is machined to accommodate different kinds of active or passive flow control valves.

- The screen is then wrapped as per client specifications directly on the pipe.

- Rings and covers are manufactured with high precision as per clients request, then assembled and welded into the basepipe.

Applications

- Suitable for flow control applications with or without sand control.

- Suitable for vertical, deviated and horizontal completions.

Benefits

- Installations with flow control devices.

- Optimized flow performance into the basepipe.

- Control of unwanted water/gas production.

- Can be re-configured to fit other applications.

Features

- No elastomers, all-welded construction.

- Simple construction.

- Robust design.

- Oil & Gas Equipment

- DynamicLink Downhole Screen

- Sand Control

Openhole System

Overview

- The DynamicLink Screen open hole system is a profile wire screen completion system, designed to achieve laminar flow conditions primarily in long horizontal wells. The profile wire design helps maximize sand free production that resists damage and erosion for effective, long term sand control.

- The DynamicLink no base pipe screen is robust yet lightweight. It is suitable for high mechanical loads, short radius wellbores, and wells with high rate gas flow conditions. It can also be used with or instead of current completion systems.

- Whereas conventional sand screens are affected by high inflow velocity of gas or liquid, DynamicLink screens feature specially engineered profiles that force inflow to be distributed more uniformly over a longer length of screens compared with that of conventional screens. This reduces velocity and eliminates erosion hot spots through laminar flow regimes without the need to choke production.

Applications

- Onshore and Offshore wells.

- Stand-alone completions.

- High Rate Gas environment.

- Thermal applications, including heavy-oil and steam assisted wells.

Features

- No Base Pipe - Minimal Flow restriction.

- Robust design.

- Suitability for Short- Radius well profiles.

- Ability to clear / stimulate through entire joint.

Benefits

- Higher reservoir drainage.

- Longer Laminar flow preventing erosion.

- Longer well life and optimized production.

- Oil & Gas Equipment

- DynamicLink Downhole Screen

- Sand Control

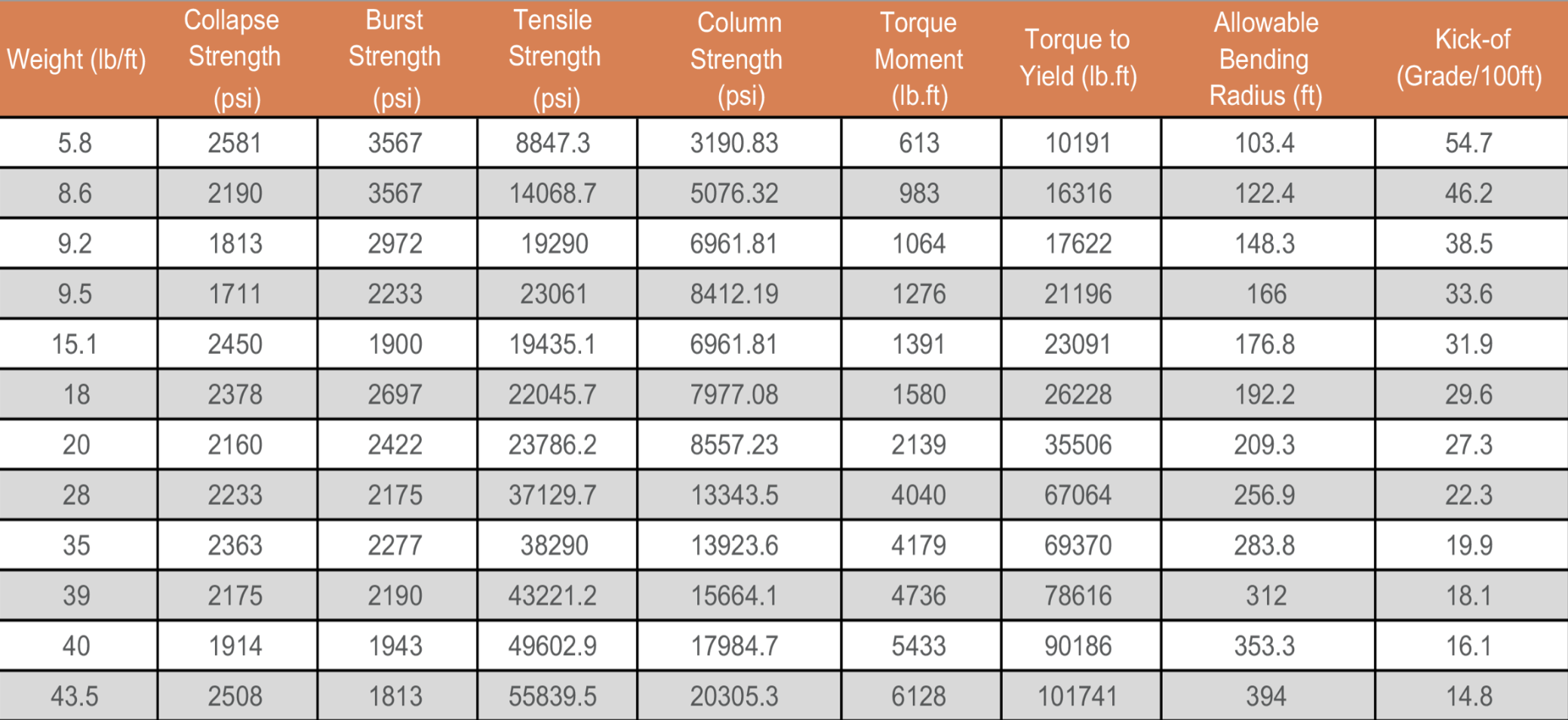

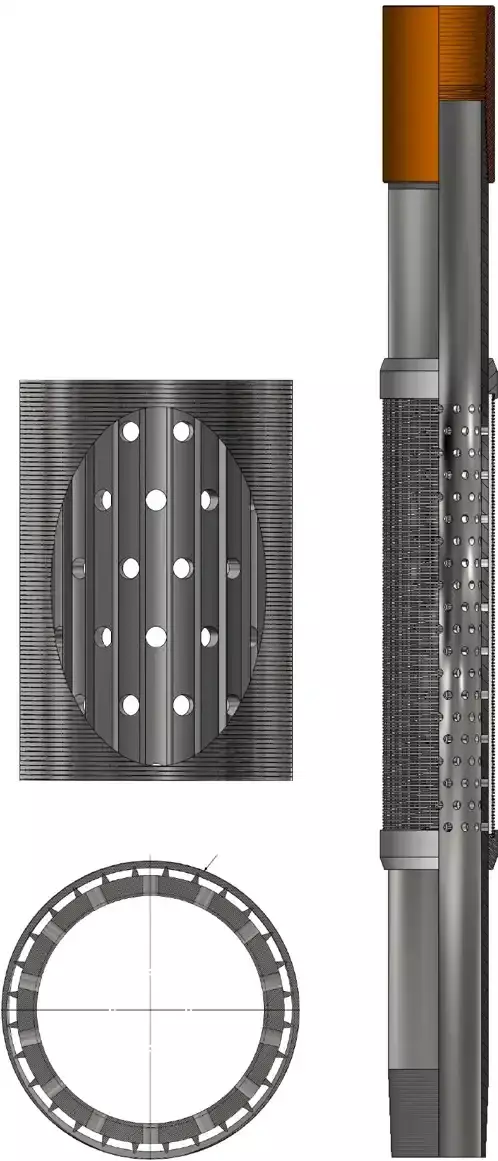

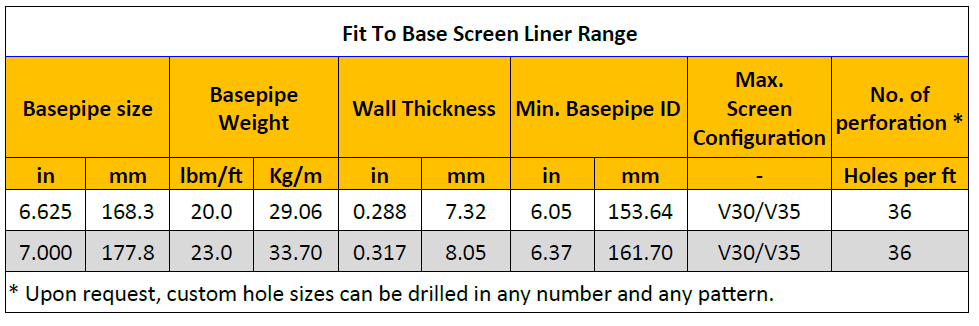

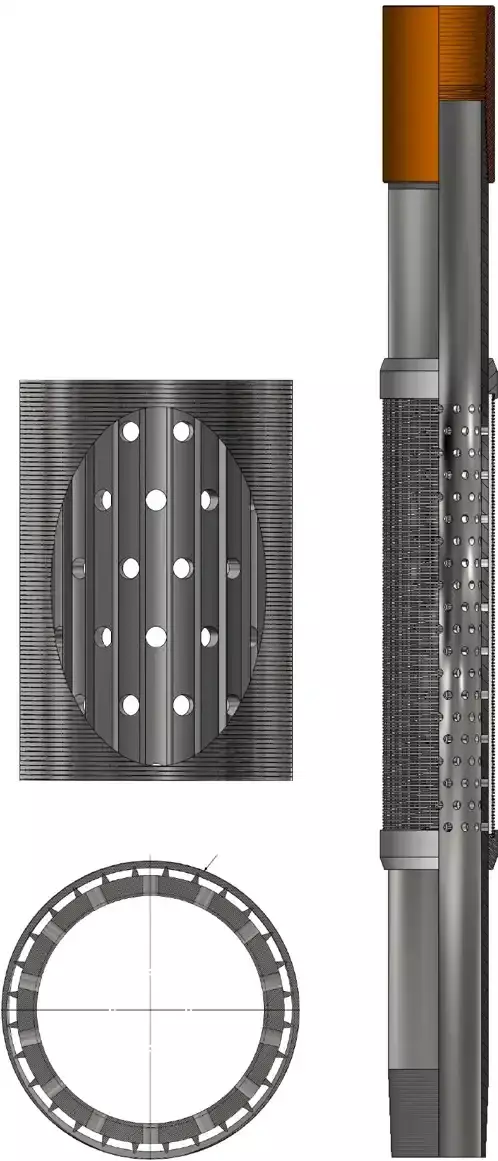

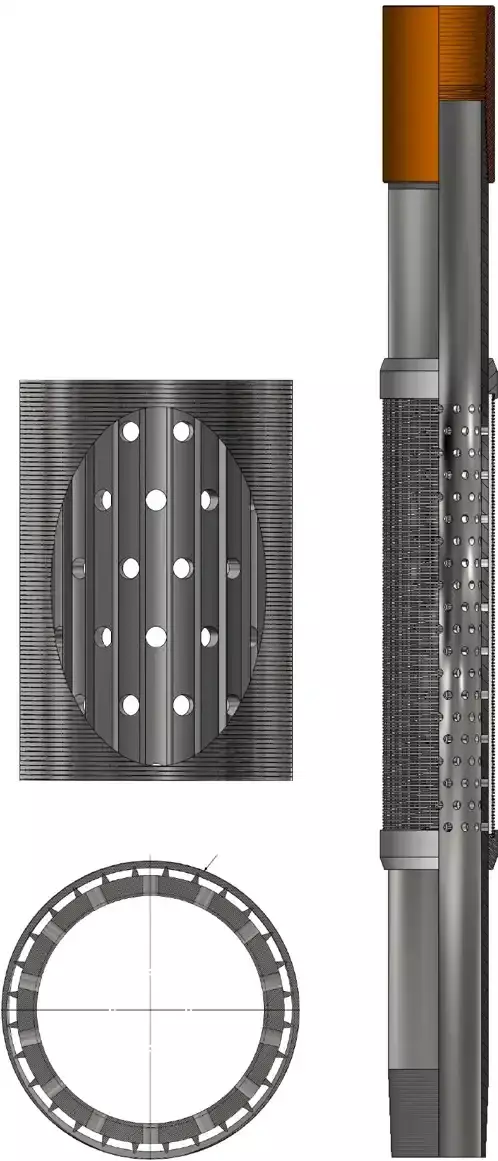

Fit To Base Screen on Perforated Basepipe

Overview

- This product consists of a wire wrapped screen on a perforated base pipe up to 7”OD & 39ft length.

- The screen can be manufactured up to a total length of 28ft (8.5 meters) on the pipe. Meanwhile the joint is perforated casing with a 39ft (12 meters) bed length - 8 spindle drilling machine.

- The DOT standard spiral and staggered perforation patterns use Ø 3/8” and Ø 1/2” diameter holes, to create the client’s required open area. Upon request, custom hole sizes can be drilled in any number and / or pattern. Every joint perforated by DOT well screen is deburred internally and externally.

- The size, grade and weight of the base pipe are manufactured as per API casing/tubing specification.

Applications

- Oil and Gas wells.

- Sand control completions.

- Thermal applications, including heavy-oil and steam assisted wells.

Features

- Available in basepipe sizes ranging from 2 7/8 to 7 in. No requirement for welding on basepipe (screen wire is shrink-fitted to basepipe).

- Coherent, harmonious, and precise slot opening.

- Slot opening from 50 micron up to 2000 micron.

Benefits

- Longer laminar flow preventing erosion.

- Improved flow efficiency into basepipe.

- Longer well life and optimized production.

- Oil & Gas Equipment

- DynamicLink Downhole Screen

- Sand Control

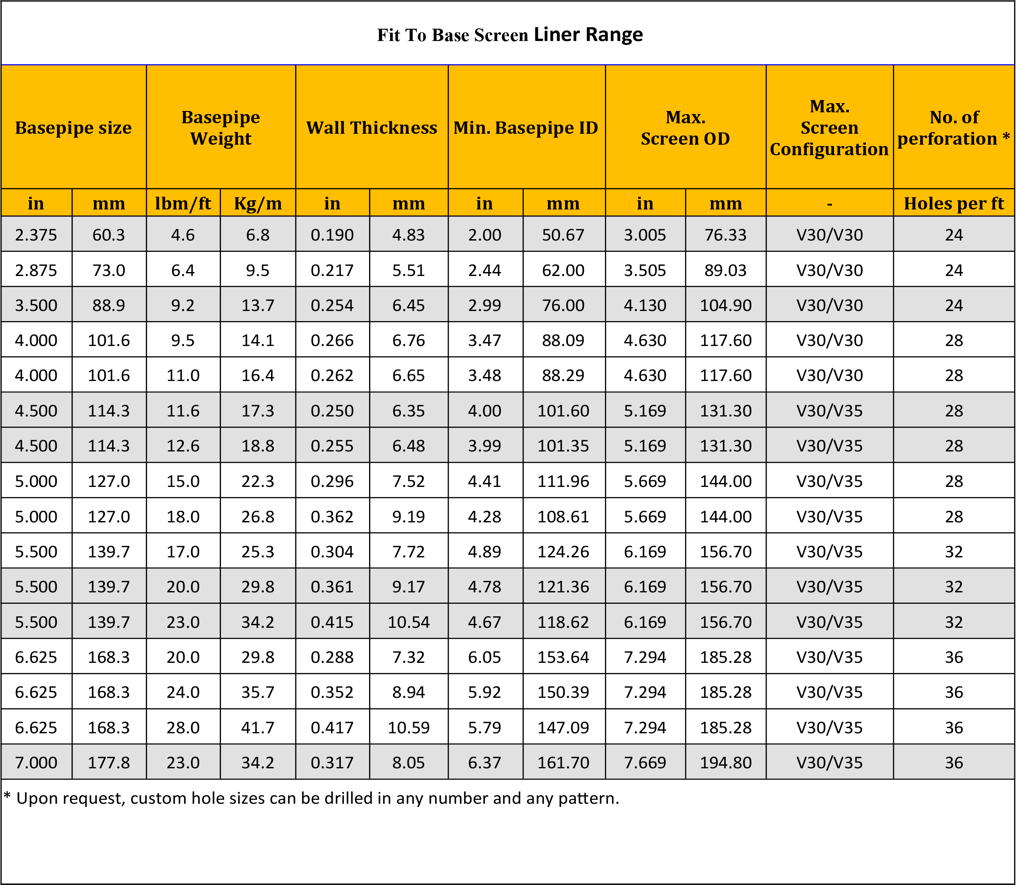

Screen Jacket on Perforated Basepipe

Overview

- This wire wrapped screen jacket is installed on a perforated base pipe up to Ø 7”- 39ft length.

- The screen can be manufactured up to a total length of 33ft (10 m), from corrosion resistant materials.

- The perforated joint is perforated with a 39ft (12m) bed length, 8 spindle Drilling machine.

- The DOT standard spiral and staggered perforation patterns use Ø 3/8” and Ø 1/2” diameter holes, to create the client’s required open area. Upon request, custom hole sizes can be drilled in any number and any pattern. Every joint perforated is deburred internally and externally.

- The screen jacket is fully pickled and passivated for maximum corrosion resistance.

Applications

- Oil and Gas wells.

- Sand control completions.

- Installations with Inflow or injection control devices.

- Thermal applications, including heavy-oil and steam assisted wells.

Features

- Available in base pipe sizes from 2 7/8 to 7 in.

- Coherent, harmonious, and precise slot opening.

- Slot opening from 50 micron up to 2000 micron.

- Customized material grades 304/316L/904/Duplex/Alloy 625.

Benefits

- Longer laminar flow preventing erosion.

- Improved flow efficiency into basepipe.

- Longer well life and optimized production.

Process Industry Screens

Overview

- DOT offers profile wire screens for several different applications. Each profile wire screen product is custom designed to suit the specific requirements of the customer and provides high-performance solutions.

- Some of the applications where profile wire screens can be found are:

Applications

- Mining and Mineral Processes.

- Water Treatment Processes.

- Food and Beverage Industry.

- Chemical and Pharmaceutical Industry.

- Oil & Gas Industry.

Benefits & Features

- Wide range of profile wires are available to suit most systems.

- Low maintenance costs: Separation at the screen surface which can be easily cleaned by scraping or back washing

- Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

- Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP).

- Chemical and thermal resistant: A variety of corrosion resistant stainless-steel materials and many exotic alloys suitable for high temperatures and pressures.

- Long life: Welded at each intersection creating a strong and durable screen.

Mining and Mineral Processes

Applications

- Coal

- Potash

- Salt

- Sand

- Pulp

- Paper

- Other Chemicals

- Process Industry Screens

- Mining and Mineral Processes

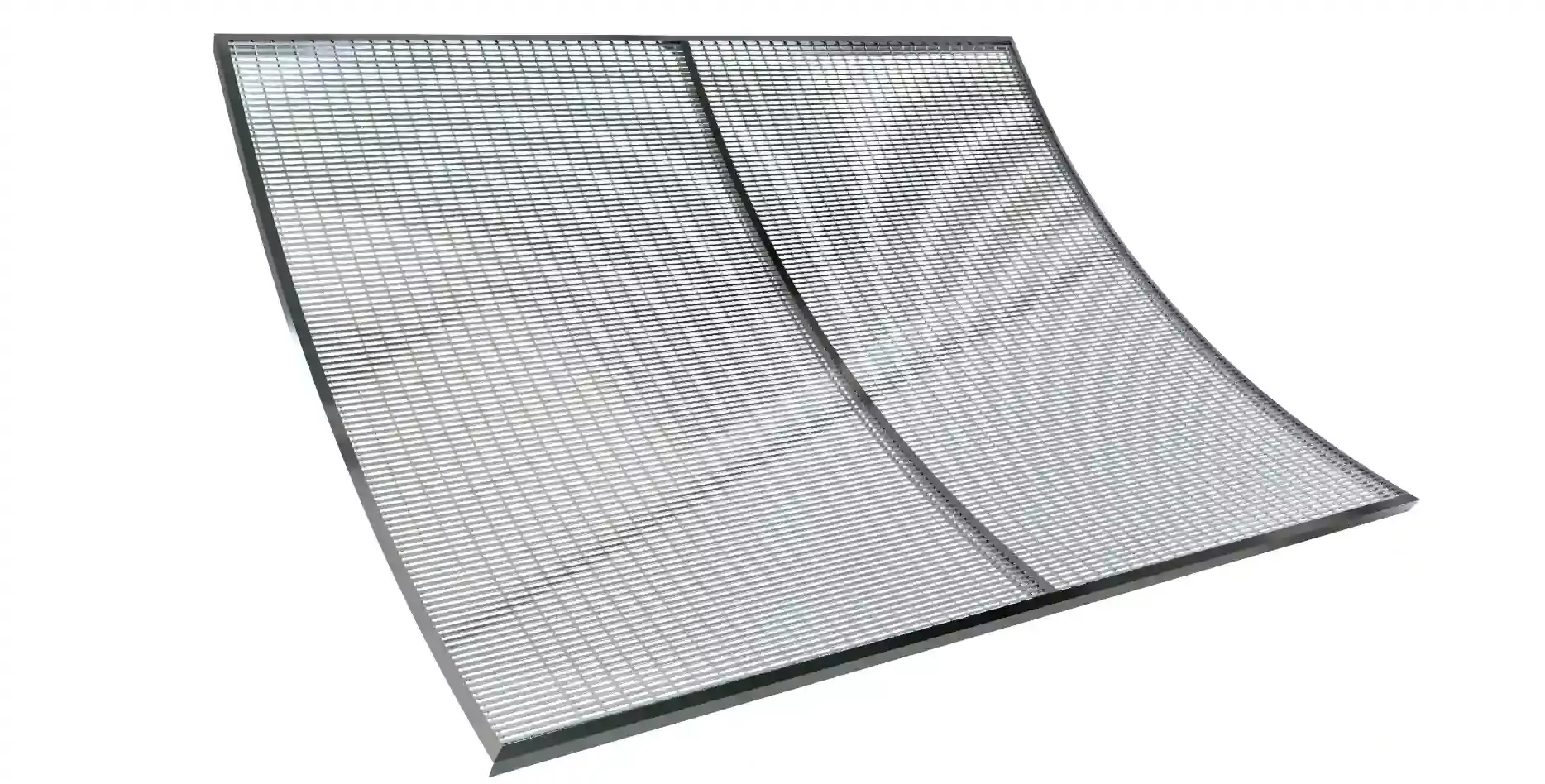

Flat Panels

Advantages

- High abrasion and corrosion resistance

- High temperature resistance

- Balanced and self-supporting

- Low pressure drop

- High durability

- Easy Installation

- No-clogging structure

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Mining and Mineral Processes

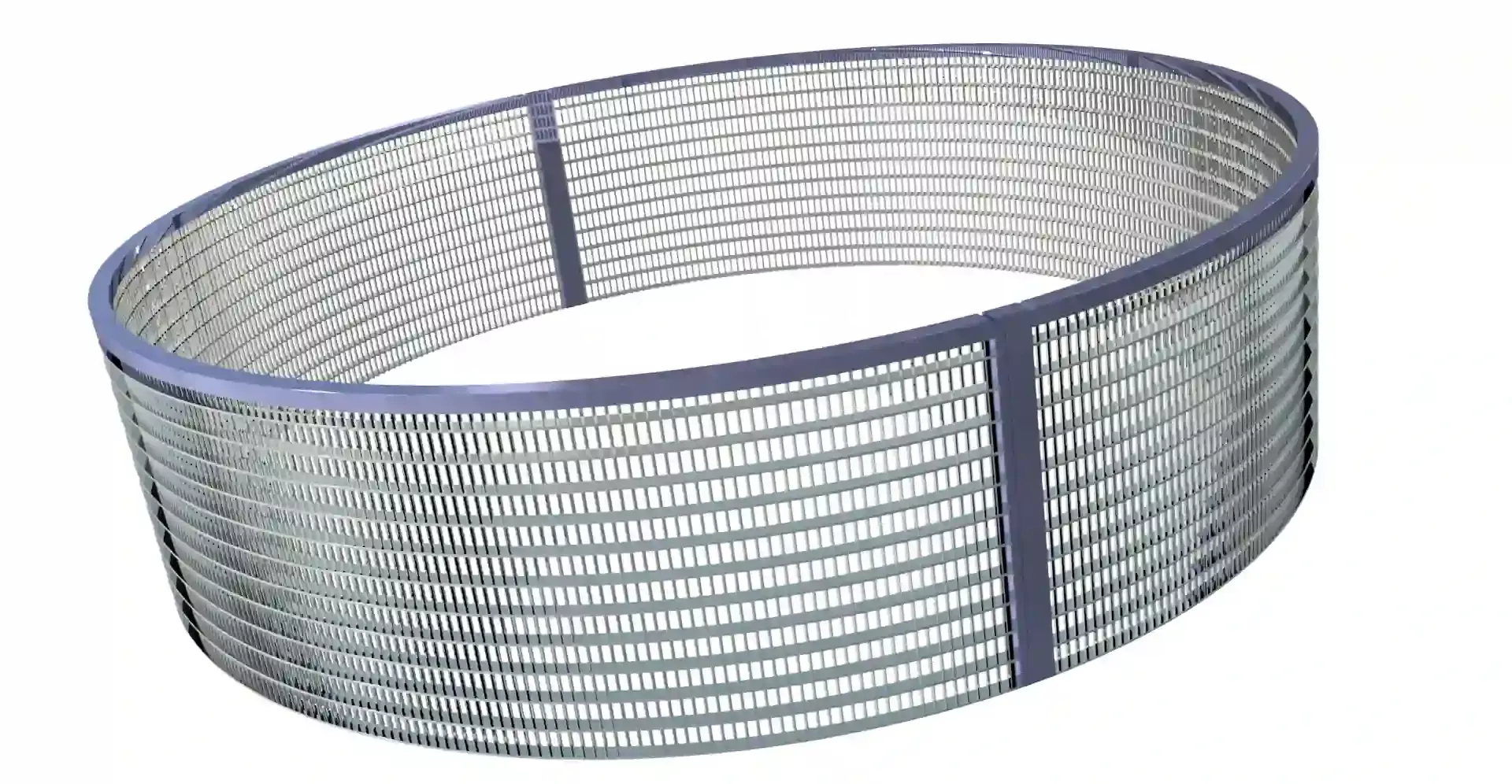

Sieve Bends

Advantages

- High abrasion and corrosion resistance

- High temperature resistance

- Balanced and self-supporting

- Low pressure drop

- High durability

- Easy Installation

- No-clogging structure

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Mining and Mineral Processes

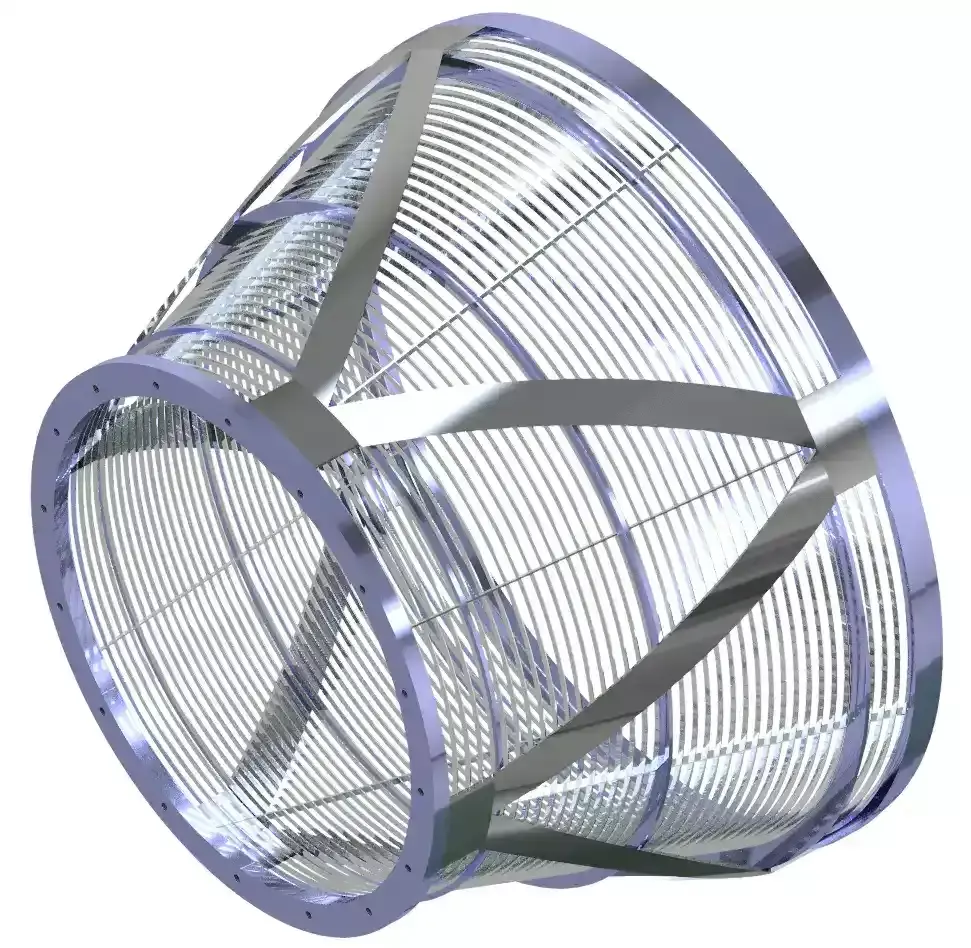

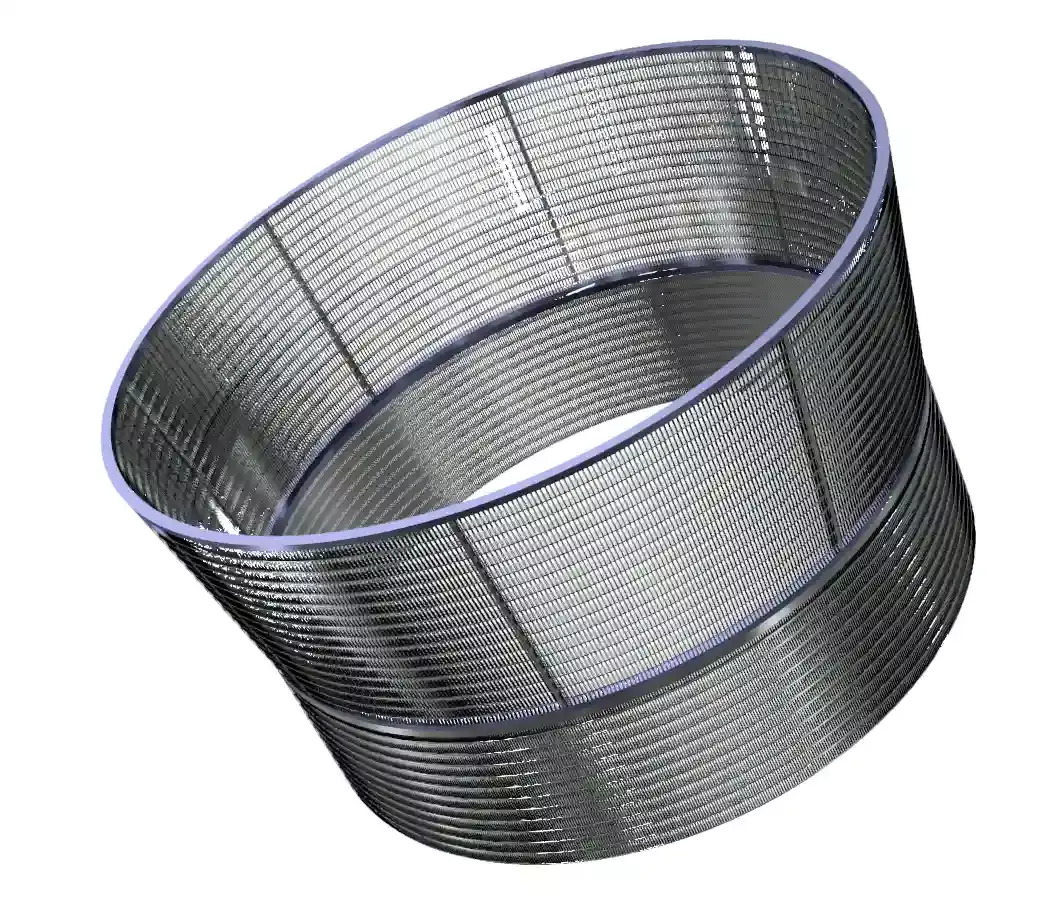

Centrifuge Baskets

Advantages

- High abrasion and corrosion resistance

- High temperature resistance

- Balanced and self-supporting

- Low pressure drop

- High durability

- Easy Installation

- No-clogging structure

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

Water Treatment Processes

- Process Industry Screens

- Water Treatment Processes

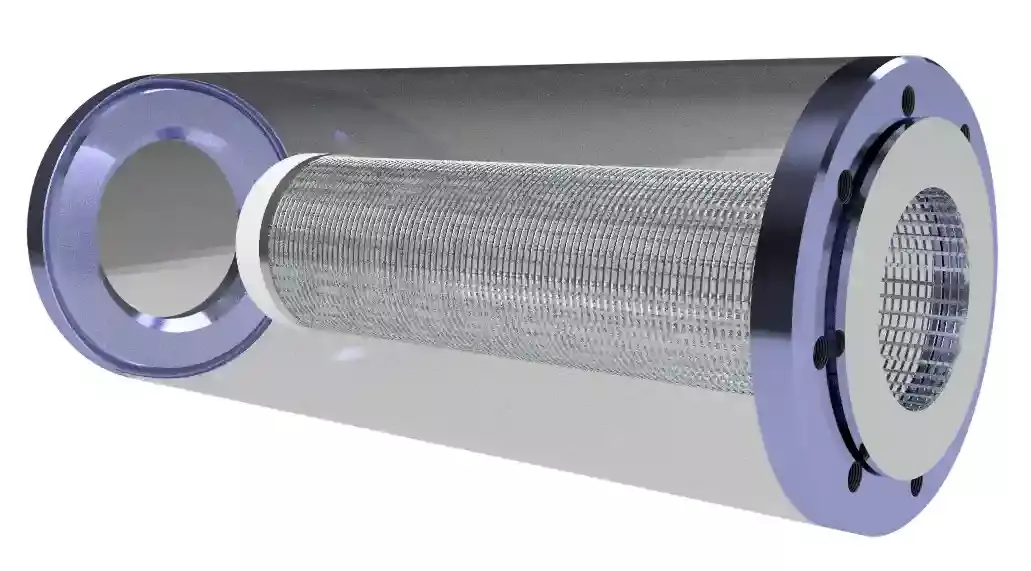

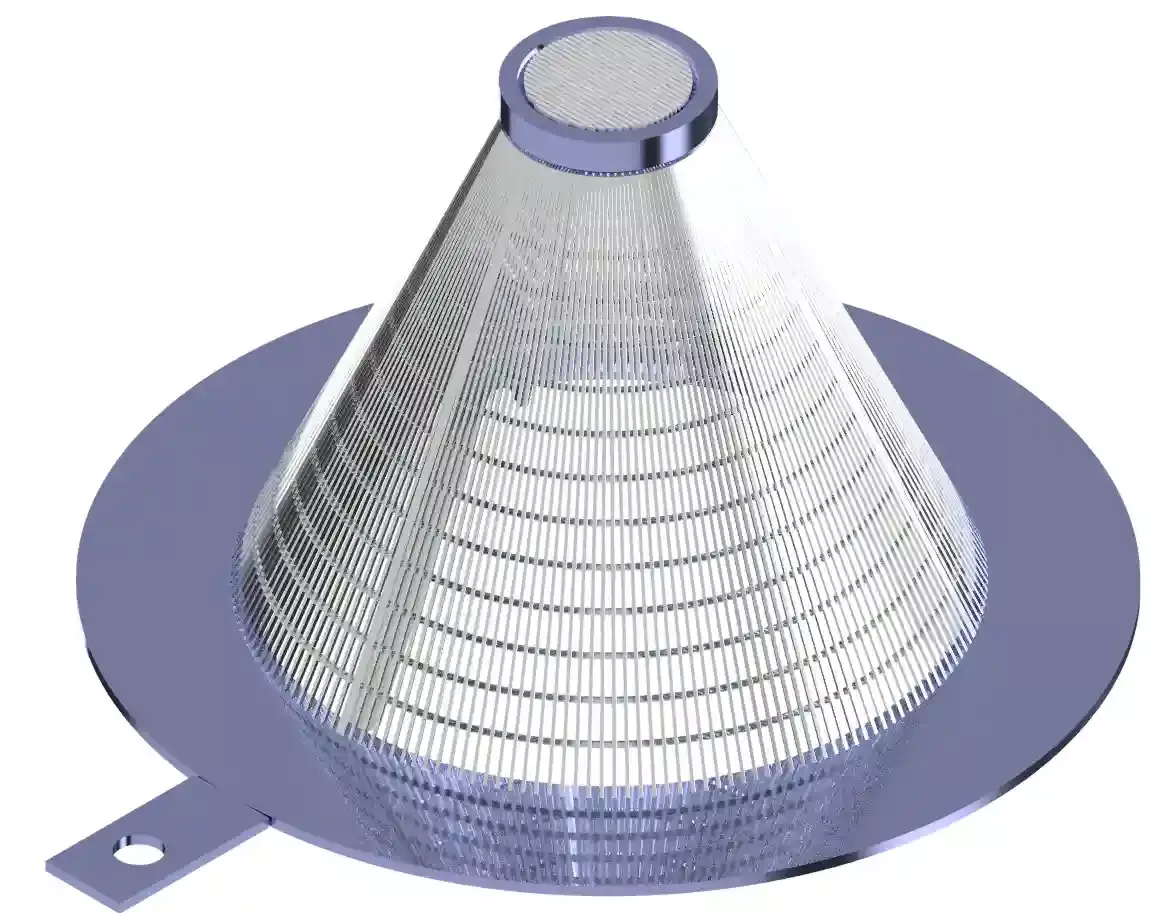

Resin Traps with Housing

Advantages

- Easy to maintain

- Strong and durable

- Extreme applications

- Minimal pressure drops

- High open area and precise opening

- High abrasion and corrosion resistance

- High temperature resistance

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Water Treatment Processes

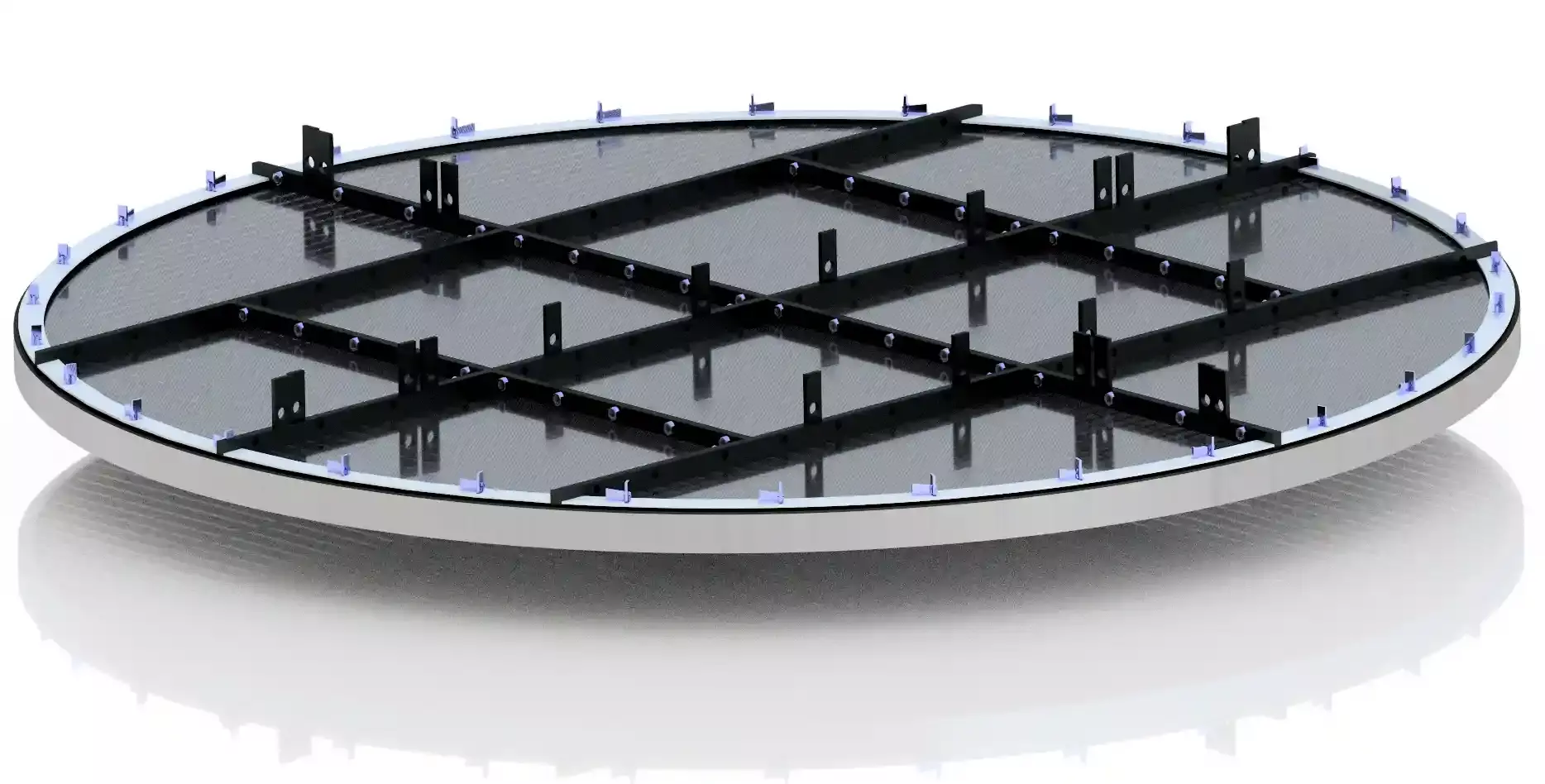

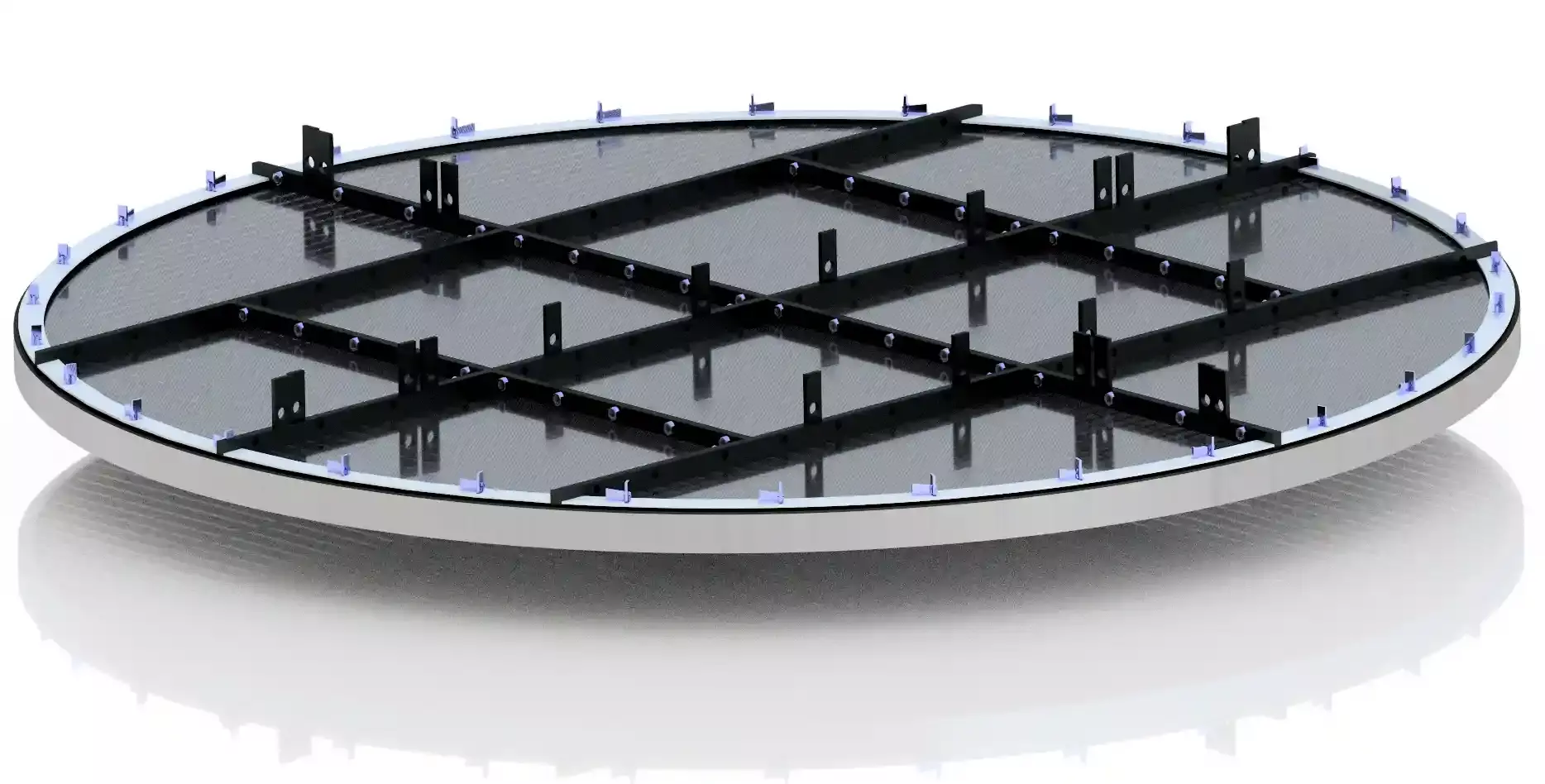

Screen Support Grids

Advantages

- Easy to maintain

- Strong and durable

- Extreme applications

- Minimal pressure drops

- High open area and precise opening

- High abrasion and corrosion resistance

- High temperature resistance

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Water Treatment Processes

Sea Water Intake Screens

Advantages

- High strength and durability

- No moving parts

- Reliable system for aquaculture protection

- Maximum water flow

- High abrasion and corrosion resistance

- High temperature resistance

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

Food and Beverage Industry

Applications

- Food processes

- Brewing Processes

- Sugar Processes

- Corn Wet Milling

- Fruit extraction

- Coffee and cacao processes

- Process Industry Screens

- Food and Beverage Industry

Screen Baskets

Advantages

- Strong and durable

- Wide range of profile wire is available to suit most systems

- Smooth surface and long service life

- Easy of replacement will reduce downtime

- Easy to clean and backwash

- High abrasion and corrosion resistance

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Food and Beverage Industry

Flat Sieves

Advantages

- Strong and durable

- Wide range of profile wire is available to suit most systems

- Smooth surface and long service life

- Easy of replacement will reduce downtime

- Easy to clean and backwash

- High abrasion and corrosion resistance

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Food and Beverage Industry

Screen Support Grids

Advantages

- High strength and durability

- No moving parts

- Reliable system for aquaculture protection

- Maximum water flow

- High abrasion and corrosion resistance

- High temperature resistance

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

Chemical and Pharmaceutical Industry

Applications

- Paints

- Gas absorbers

- Base Chemicals

- Acids

- Resins

- Inks

- Process Industry Screens

- Chemical and Pharmaceutical Industry

Filter Nozzle

Advantages

- High strength and durability

- Easy to install and replacement

- High filtering performance

- Corrosion and rust resistance

- High temperature resistance

- Various ending types.

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Chemical and Pharmaceutical Industry

Collector/Distribution Screen

Advantages

- High strength and durability

- Easy to install and replacement

- High filtering performance

- Corrosion and rust resistance

- High temperature resistance

- Various ending types.

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Chemical and Pharmaceutical Industry

Centrifuge Screen Baskets

Advantages

- High filtration efficiency

- Long service life

- High abrasion and corrosion resistance

- High temperature resistance

- High open area and precise opening

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

Oil & Gas Industry

Applications

- Protection of pumps, Valves etc.

- Standard coiled tubing.

- Abrasive pumping

- Process Industry Screens

- Oil & Gas Industry

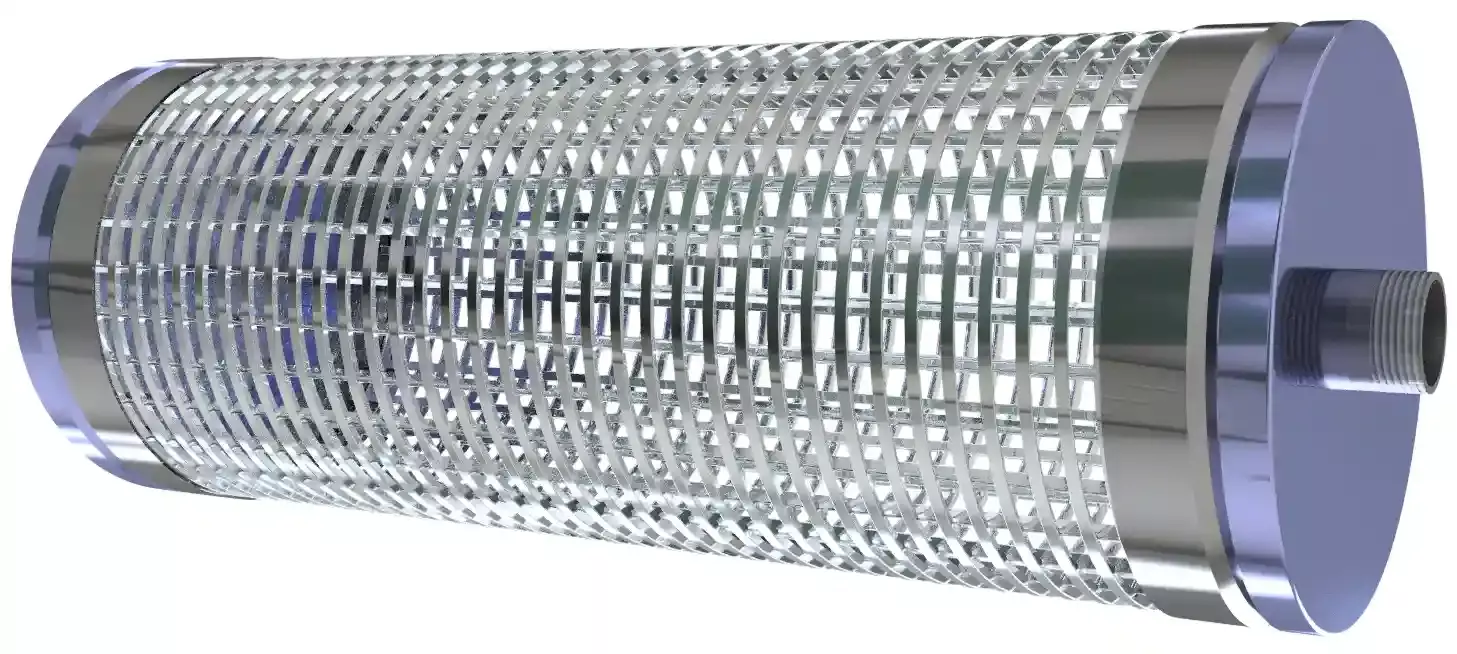

Inline Surface Filter

Advantages

- Consistency of viscosity and smoothness

- The highest levels of product security

- Designed to allow fluids to pass, but traps debris

- High abrasion and corrosion resistance

- High temperature resistance

- Easy to install and replace

- High filtering efficiency without clogging

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Oil & Gas Industry

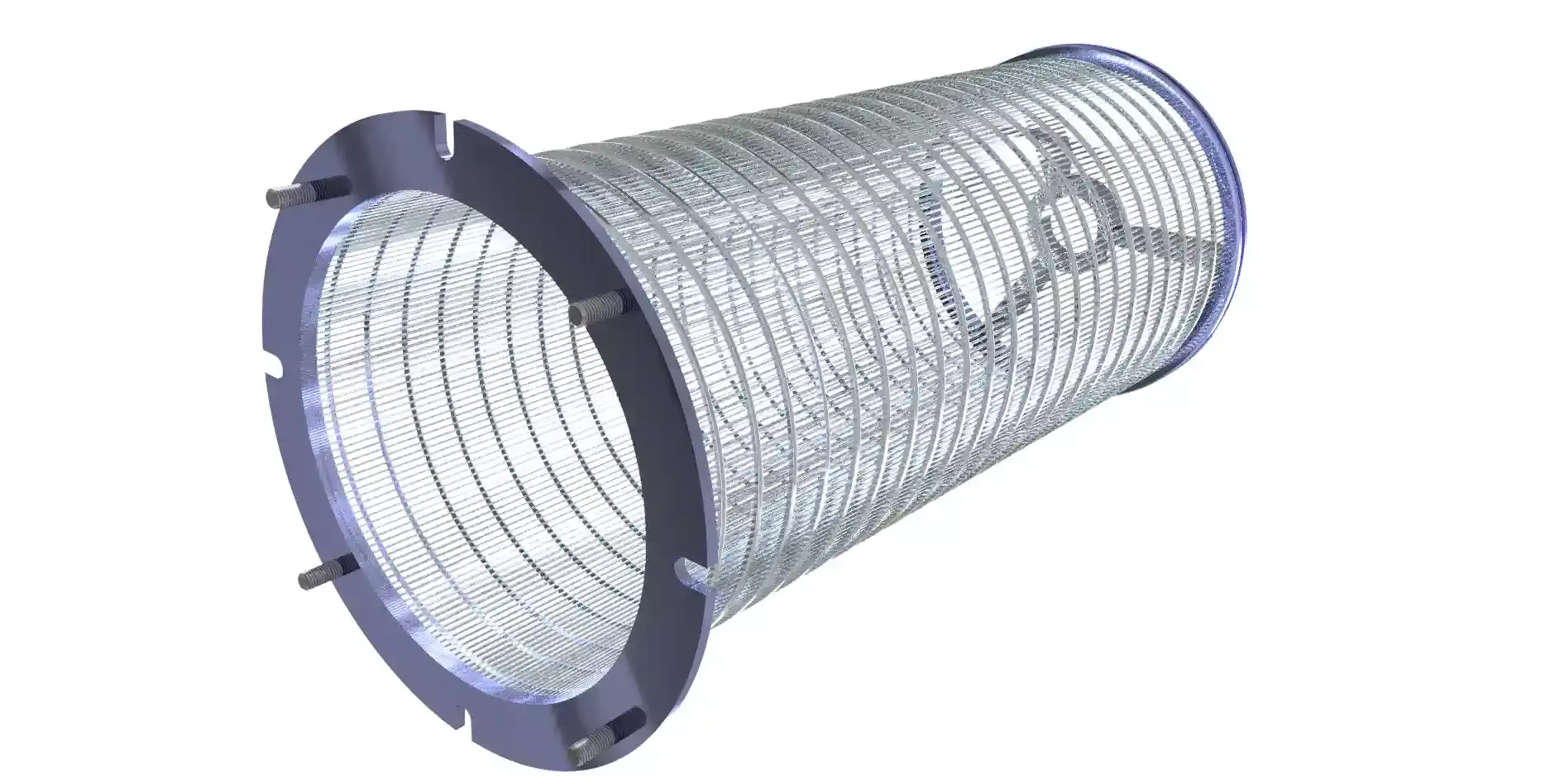

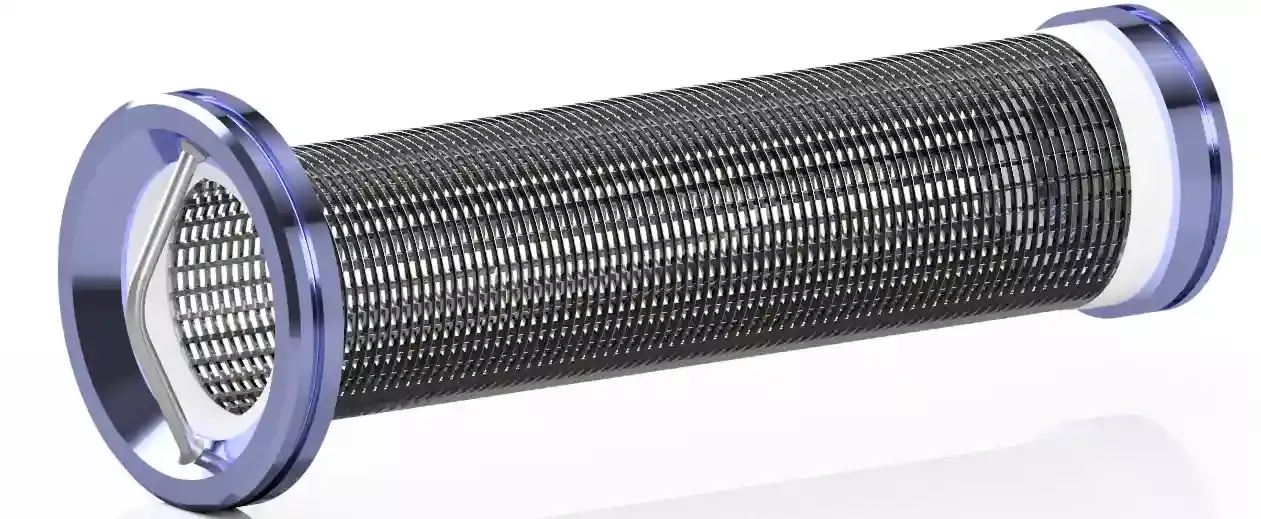

Well Test Screen

Advantages

- Consistency of viscosity and smoothness

- The highest levels of product security

- Designed to allow fluids to pass, but traps debris

- High abrasion and corrosion resistance

- High temperature resistance

- Easy to install and replace

- High filtering efficiency without clogging

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

- Process Industry Screens

- Oil & Gas Industry

Strainers

Advantages

- High filtration efficiency

- Can be installed either vertically or horizontally

- Profile wire strainer provide greater open area than perforated mesh strainer

- Particles are retained by the screen and can be easily re moved for disposal

- Wide range of profiled wire are available to suit most systems

Technical Specification

- Materials: All grades of stainless steel, duplex, super duplex, alloy, etc.

- Sizes: In accordance to client's requirement.

- Slot ranges: 50 microns and above

Ground Water Well Screens

- Ground Water Well Screens

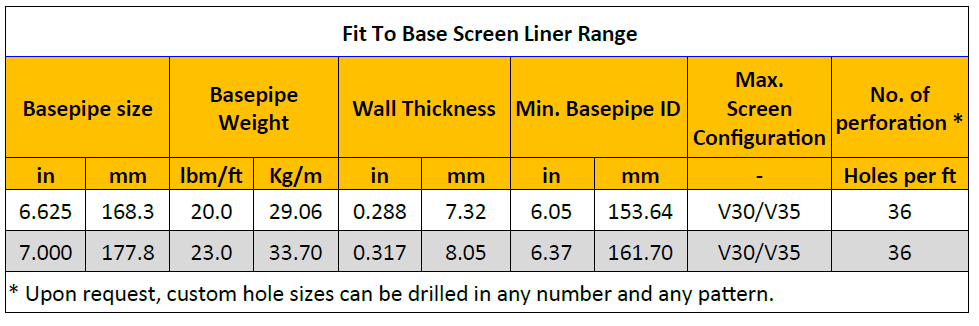

Fit To Base Screen on Perforated Basepipe

Overview

- This product consists of a wire wrapped screen on a perforated base pipe up to Ø 7”-39ft length.

- The screen can be manufactured up to a total length of 8.5 meters on the pipe. Meanwhile the perforated liner or pre-perforated casing is manufactured with a 12m bed length - 8 spindle Drilling machine.

- The DOT standard spiral and staggered perforation patterns use Ø 3/8” and Ø 1/2” diameter holes, to create the client’s required open area. Upon request, custom hole sizes can be drilled in any number and / or pattern. Every joint perforated by DOT well screen is deburred internally and externally.

- The size, grade and weight of the base pipe are manufactured as per API casing/tubing specification.

Applications

- Groundwater Wells

Features

- Available in base pipe sizes ranging from 2 7/8 to 7 in.

- No requirement for welding on base pipe (screen wire is shrink- fitted to base pipe).

- Slot opening from 50 micron up to 2000 micron, which can be customized based on well specifications.

- Customized material grades 304/316L/904/Duplex/Alloy 625.

Benefits

- Improved water flow efficiency into base pipe.

- Optimized inflaw peformance.

- Longer well life and optimized production

- Ground Water Well Screens

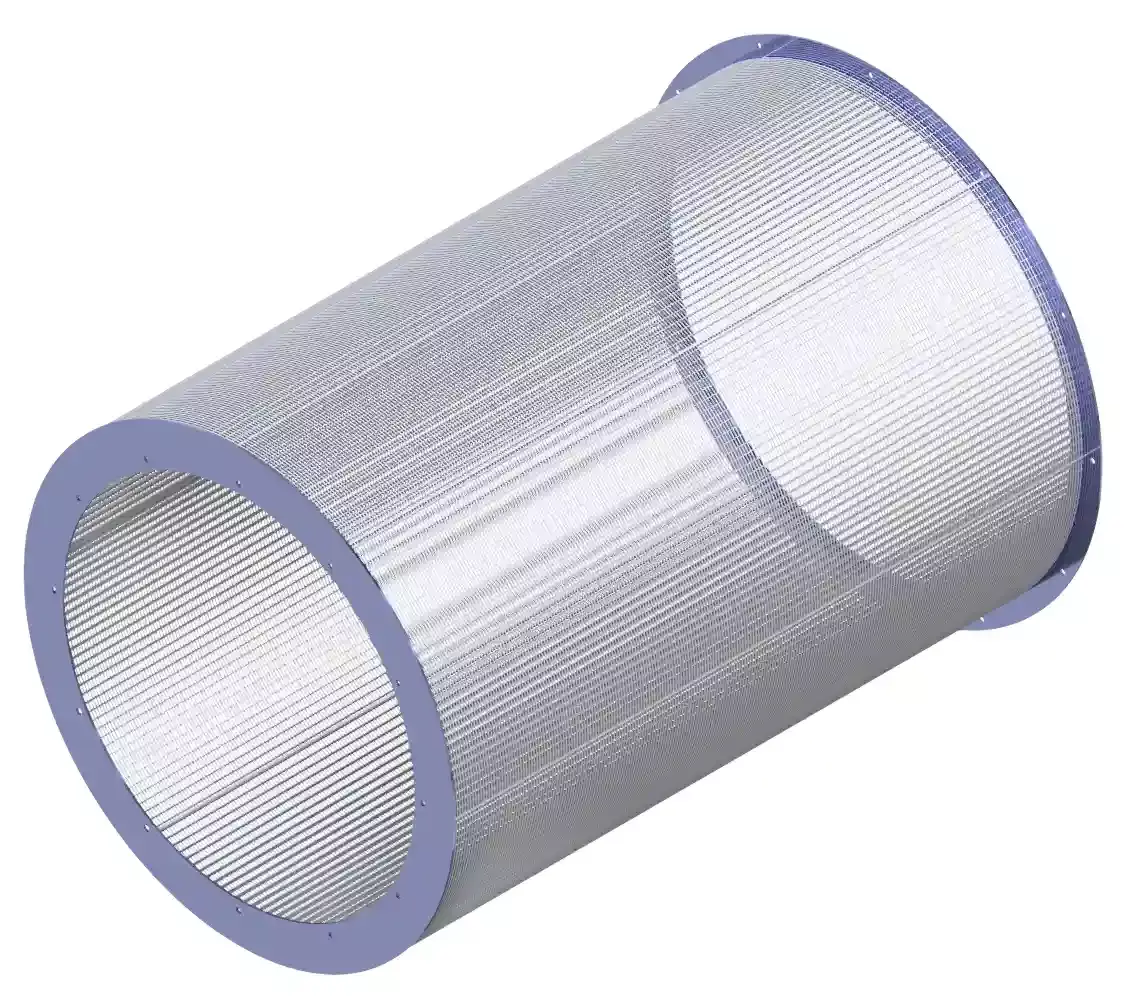

Screen Jacket on Perforated Base Pipe

Overview

- This wire wrapped screen jacket is installed on a perforated base pipe up to Ø 7”- 39ft length.

- The screen can be manufactured up to a total length of 10 m, from corrosion resistant materials.

- The perforated liner or pre-perforated casing is manufactured with a 12m (39ft) bed length, 8 spindle Drilling machine.

- The DOT standard spiral and staggered perforation patterns use Ø 3/8” and Ø 1/2” diameter holes, to create the client’s required open area. Upon request, custom hole sizes can be drilled in any number and any pattern. Every joint perforated is deburred internally and externally.

- The size, grade and weight of the base pipe are manufactured as per API casing/tubing specification.

- The screen jacket is fully pickled and passivated for maximum corrosion resistance.

Applications

- Groundwater Wells

Features

- Welded rings isolate jacket from mechanical loads on base pipe

- Available in base pipe sizes from 2 7/8 to 7 in.

- Multiple unique surface and support wire profile options

- Slot opening from 50 micron up to 2000 micron, which can be customized based on well specifications.

- Customized material grades 304/316L/904/Duplex/Alloy 625.

Benefits

- Low laminar flow preventing erosion

- Optimized inflow performance

- Improved water flow efficiency into base pipe

- Longer well life and optimized production

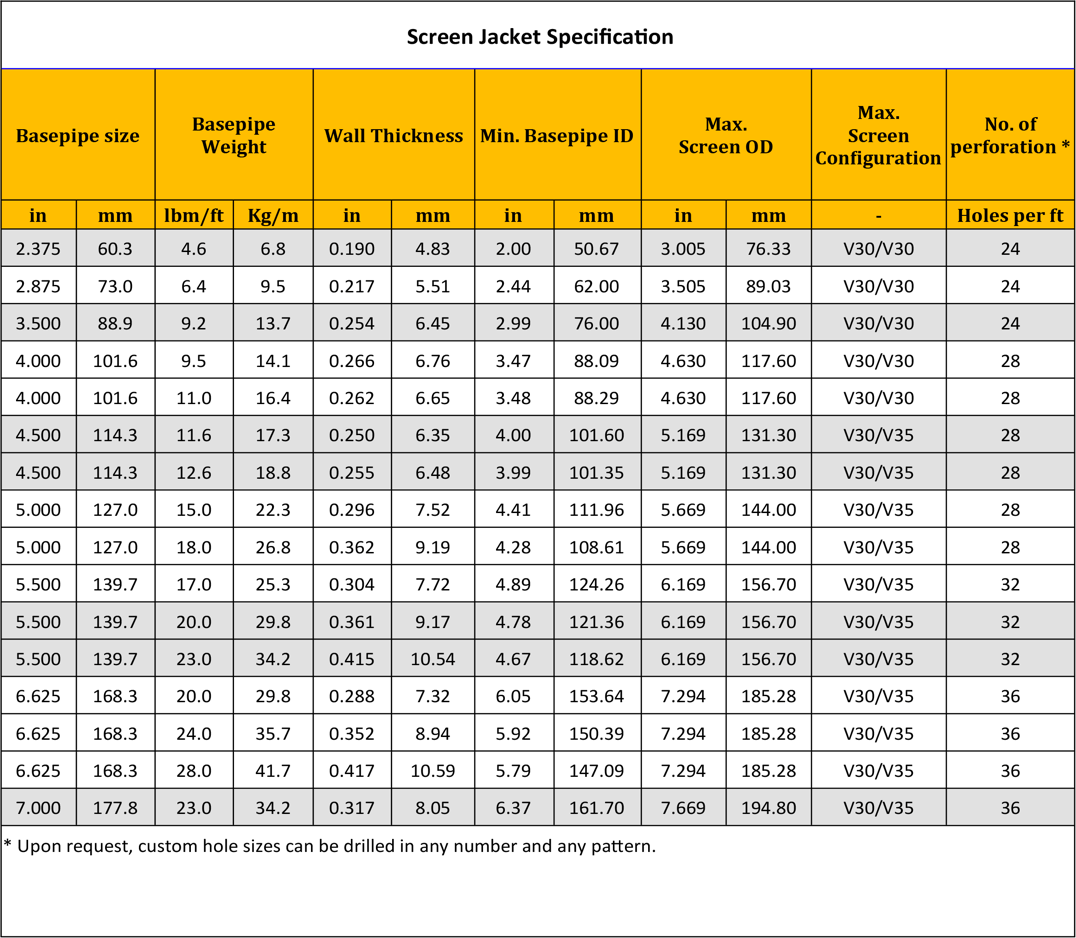

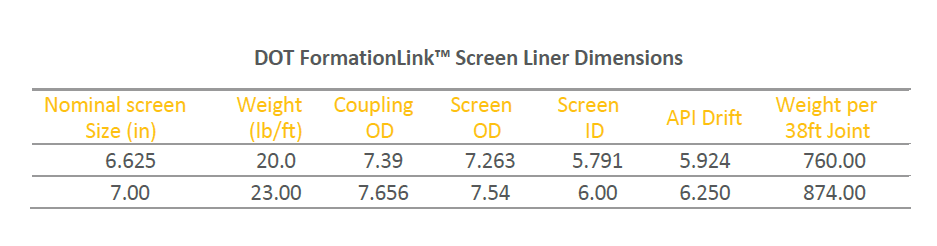

DynamicLink Screen Liner

- DynamicLink Screen Liner

Open hole System

Overview

- The DynamicLink Screen Liner open hole system is a profile wire screen completion system, designed to achieve laminar flow conditions primarily in long horizontal wells. The profile wire design helps maximize sand free production that resists damage and erosion for effective, long term sand control.

- The DynamicLink no base pipe screen is robust yet lightweight. It is suitable for high mechanical loads, short radius wellbores, and wells with high rate gas flow conditions. It can also be used with or instead of current completion systems. While conventional sand screens are affected by high inflow velocity of gas or liquid, DynamicLink screens feature specially engineered profiles that force inflow to be distributed more uniformly over a longer length of screens compared with that of conventional screens. This reduces velocity and eliminates erosion hot spots through laminar flow regimes without the need to choke production.

Applications

- Groundwater Wells

Features

- No Base Pipe - No Flow restriction

- Robust design - resistance to plugging

- Suitability for Short - Radius well profiles

Benefits

- Higher reservoir drainage

- Low laminar flow preventing erosion

- Longer well life and optimized production

- Resists plugging

DynamicLink Screen Liner

Design

- This screen, with no base pipe, is designed through forming V-SLOT openings with the venturi nozzle profile.

- This is done by configuring two adjacent profiled wires. The no base pipe screens are manufactured using a standardized process that assembles and welds all wire layers in a single systematic operation.

- The structural design of the screen uses the basic mass research technique to calculate its permeability, which depends on the screen chosen structure. This technique considers the permeability and flow characteristics for unconsolidated formations in laminar, transition, and turbulent flows.

Newsletter

Copyright Dynamic Oil Tools © [phlox_year]. All rights reserved.